Sustainable Bananatex goes mainstream

OK, the Abacá-derived material has been on a five-year journey from conception to scaled-up production, so it is not exactly earth-shattering news. However, with Bananatex finally going mainstream, it can be added to the roster of manufacturing options that take us beyond the only recently recognised menace of synthetic, oil-based horrors.

What is Bananatex?

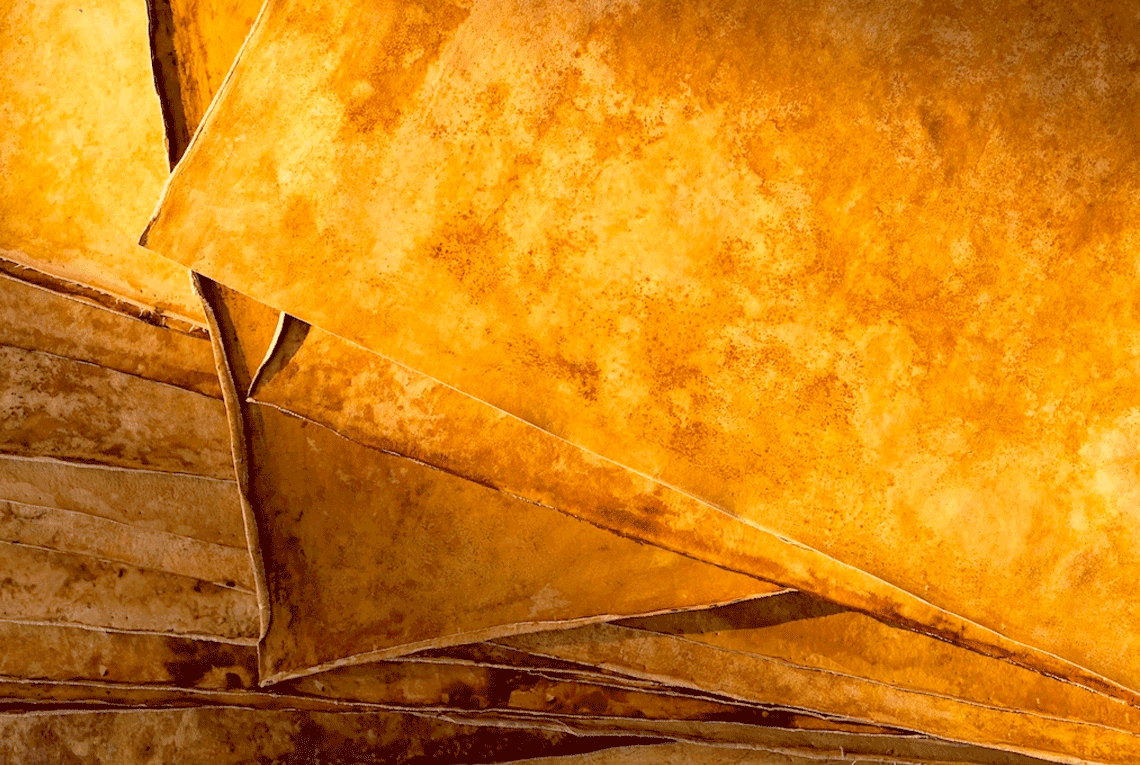

Good question: Bananatex is a fabric made from the fibres of the Abacá banana plant, which is grown in the Philippines. It is a natural, biodegradable, and durable material that can be used for various applications, such as bags, clothing, and accessories. Bananatex was developed by an Austrian/Swiss bag brand, QWSTION, in collaboration with a yarn specialist and a weaving partner in the Far East. As far as we can figure, Bananatex is the world’s first technical fabric made from banana fibre, and it has won several awards for its sustainability and design.

Also known as Manila hemp, this plant is especially known for its strong and versatile fibres. Bananatex is a textile innovation that utilizes these fibres to create a sturdy and eco-friendly material suitable for various products, particularly in the fashion and accessories industry.

Interestingly, it exhibits properties similar to traditional synthetic materials, such as nylon, while being more environmentally friendly. The resulting fabric is lightweight, yet robust, and has natural water-resistant qualities, making it suitable for use in the production of bags, backpacks, and other outdoor gear.

Rightly touted for its sustainable credentials, it is a renewable and biodegradable material that can help take a bite out of the environmental impact of synthetic textiles. Additionally, the cultivation of Abacá plants can contribute to the livelihoods of local communities in regions where these plants are grown, providing economic opportunities and supporting sustainable agricultural practices.

As a result of its eco-friendliness and durability, Bananatex has garnered attention from consumers and businesses seeking more sustainable alternatives to conventional synthetic materials, contributing to the ongoing efforts to promote environmentally responsible practices in the fashion and textile industries.

There are some other fabrics that are similar to Bananatex in terms of being made from natural, biodegradable, and renewable sources. Some examples are:

- Piñatex: A fabric made from the fibres of pineapple leaves, which are usually discarded after harvesting the fruit. Piñatex is a vegan and cruelty-free alternative to leather, and it can be used for fashion, accessories, and upholstery. Piñatex was created by Dr. Carmen Hijosa, a Spanish entrepreneur and designer, who founded the company Ananas Anam to produce and distribute the fabric.

- Orange Fiber: This one is a fabric made from the cellulose fibres extracted from the peels of citrus fruits, which are usually wasted after juicing. Orange Fiber is a soft, silky, and breathable material that can be blended with other fibres and dyed with natural or synthetic colours. Orange Fiber was developed by Adriana Santanocito and Enrica Arena, two Italian entrepreneurs and innovators, who founded the company “Orange Fiber Srl” to produce and market the product.

Organic, synthetic leather, is this finally the Real-Deal?

You hate PVC as much as we do? Good – welcome to Mushroom Leather, a material made from the mycelium, the root structure of mushrooms, which can grow on organic waste such as sawdust, straw, or corn stalks. Mushroom Leather is a vegan and compostable alternative to animal leather, and it can be used for fashion, accessories, and furniture. Just look at it – it is nothing short of gorgeous!

Philip Ross, an American artist and researcher, is the inventor of Mushroom Leather, and it was he who founded the company MycoWorks to produce and sell the material. They’re doing rather well insofar as even Hermès has been fashioning it into seriously high-end accessories, and they have attracted serious Series B funding to power their scale-up

Philip Ross, an American artist and researcher, is the inventor of Mushroom Leather, and it was he who founded the company MycoWorks to produce and sell the material. They’re doing rather well insofar as even Hermès has been fashioning it into seriously high-end accessories, and they have attracted serious Series B funding to power their scale-up

It is another sustainable and environmentally friendly material that can be used as a substitute for animal leather in various applications, including fashion, accessories, and even upholstery.

As the mycelium grows, it forms a network of tiny threads that bind the organic material together, creating a dense, leather-like material. This material can then be treated and processed to enhance its texture, durability, and other properties, making it suitable for different products.

Mushroom leather is often lauded for its sustainable nature, as it can be produced using fewer resources compared to traditional animal leather production. It is also biodegradable, making it an eco-friendly choice for those concerned about the environmental impact of leather production. Additionally, it can be produced without the use of harmful chemicals or toxins, further reducing its ecological footprint.

Although still relatively new in the market, mushroom leather has gained attention as a viable and ethical alternative to animal leather, catering to the growing demand for sustainable and cruelty-free materials in various industries.

We approve!

Main Image:

QWSTION Store Vienna

Zieglergasse 38

1070 Wien

Österreich