After over a century of denim manufacture, White Oak Plant closes its doors

The news came to us earlier today that made our morning coffee bitter. The Cone Denim White Oak Plant, a true pillar of the denim world, will close its doors on the 31st of December 2017.

From the Horse’s Mouth

Cone Mills is part of International Textile Group who put out this press release:

“For more than 125 years Cone Denim has defined American denim and authenticity with the White Oak mill representing the essence of Cone’s heritage,” said Kenneth T. Kunberger, President & CEO of Cone Denim and International Textile Group. “We truly regret having to take this action to close the mill, and we deeply appreciate the loyalty and dedication of all current and former employees of the White Oak mill. Their talent, effort, innovation, dedication, and customer focus all combined to create a White Oak brand, heritage, and legacy that will forever be the heart of the Cone Denim business.”

Over a Century of Tradition

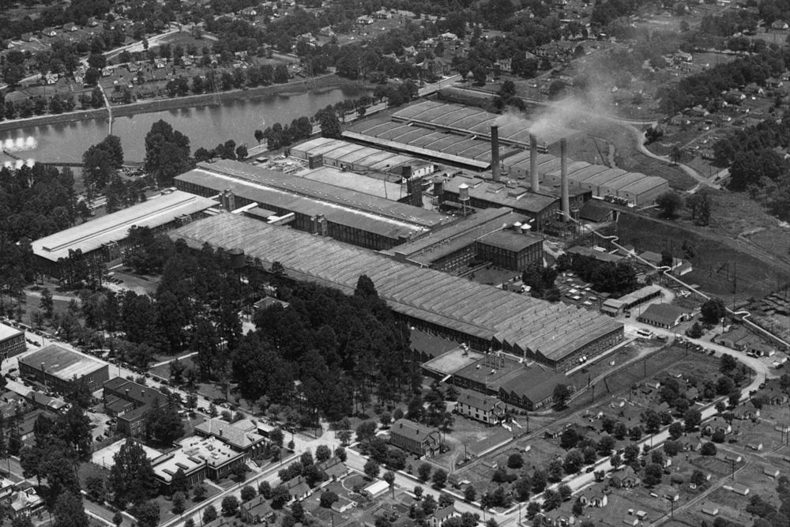

Founded in 1891 by brothers Moses and Ceasar Cone, Cone Denim has literally woven itself into the fabric of jeans culture and culture in general over a time period spanning three centuries and the White Oak Plant has been in continuous operation from its inception in 1905.

With the resurgence of quality selvedge denim, the White Oak plant was the go-to mill for many denim brands looking for quality selvedge denim domestically produced in the United States.

With the closure of the plant, there will be no mills in the US manufacturing selvedge denim.

What Happened?

So how did a mill that was once the biggest in the world and that carried such weight in the denim community come to the point of closing its doors? like so many of good things in this world, the simple answer is money.

In a statement, owners ITC claimed;

“Changes in market demand in recent years have significantly reduced order volume at the facility. The cost of operating a cavernous plant with a fraction of its peak production levels was too high.”

That then begs a couple of questions; why was the idle floor-space not mothballed and why were order lead-times reportedly some of the longest in the industry? Simply blaming “the market” looks, to us, like being only part of the story.

Nonetheless, Cone Denim has been struggling against cheap imports since the 70s and, with NAFTA decimating the textile industry in North America in the mid-90s, White Oak represented a beacon of hope as Cone became a leading manufacturer of Selvedge Denim, made on the “old style” Draper looms.

White Oak became seen as an innovative survivor in this turbulent economy but the writing had been on the wall for a while. 2008/9 saw layoffs of 250 of the 600 strong staff and over the past decade, this has waned to 200 staff members.

We can only hope and wish that these dedicated, hard-working craftsmen and women find alternative, gainful employment, and that their lives are not entirely turned upside down.

Realistically however, that is going to be challenging. Mayor Nancy Vaughan said bleakly;

“It’s a gut punch, but not unexpected,”

But is this really the end?

Well, it is certainly the end of White Oak Plant as a purely manufacturing facility. However, another Greensboro mill, Revolution Mill which closed in the 80s and manufactured flannel for Cone has had a new lease of life. It has been developed by the non-profit Self-Help into a “space for creative work and creative living”. Essentially, this means spaces for businesses and accommodation.

We can only hope that the White Oak Plant shares a similar fate and some enterprising folks eek out a corner of the 1.6 million square feet of space to house a few of the Draper Looms and continue the tradition of denim weaving at White Oak. Keep your fingers crossed folks.

Still Made In America from Cone Denim on Vimeo.