It is almost certain that at one point or another most of us have sewn on a button or two. Maybe during Home Economics classes in high school we made a pin cushion or some sort of oven glove. So how many of us have made and apron, a shirt or the Holy Grail, our own pair of jeans? Perhaps there are some unsung proficient sewers out there but for the most part, for the majority of us the aforementioned achievements are where our accomplishments as seamstresses and tailors end. However, for a few the interest and passion for creating something from the constituent parts motivates them to work wonders. For Taylor Hackbarth creating an apron was just the beginning. He is on a mission to create his whole wardrobe, from scratch, himself.

It is almost certain that at one point or another most of us have sewn on a button or two. Maybe during Home Economics classes in high school we made a pin cushion or some sort of oven glove. So how many of us have made and apron, a shirt or the Holy Grail, our own pair of jeans? Perhaps there are some unsung proficient sewers out there but for the most part, for the majority of us the aforementioned achievements are where our accomplishments as seamstresses and tailors end. However, for a few the interest and passion for creating something from the constituent parts motivates them to work wonders. For Taylor Hackbarth creating an apron was just the beginning. He is on a mission to create his whole wardrobe, from scratch, himself.

Can you tell us a little bit about yourself, what is your background?

“I’m originally from Colorado, but I spent some time in northern California where I studied music in college. Currently I live in Nashville, TN where my wife and I own and run a web and graphic design business. When I’m not sewing or working, you can usually find me in the kitchen. I love to cook almost as much as I like to make jeans.”

You clearly have a passion for clothing, how did it all begin?

“I wasn’t always as interested in clothing as I am now, but I got much more into it when I started learning how to sew and draft patterns. I love making things, and whether I’m putting together a pasta dish or making a pair of jeans, I love the “craft” aspect of taking raw ingredients, or materials in the case of clothing, and creating something that didn’t exist before. I also love history, and clothing seems to be a fun place where history and craftsmanship converge.”

This is a very interesting project you have undertaken, what was the motivation behind it?

“In the beginning I just wanted to explore something new. One night I stumbled across some people talking about denim on an online forum. I had no idea people were that passionate about denim at the time. They were talking about different brands, fit preferences, methods for washing, etc. The more I read about dry denim, the more interested I became in learning how to make a pair of jeans. Knowing absolutely nothing about clothing design, pattern making, or clothing construction was part of the appeal. It was sort of a challenge to myself. I wanted to see if I could make a pair of dry denim jeans from scratch, pattern and all, and do it without any formal training or previous experience.”

What has been the biggest challenge so far in the project?

What has been the biggest challenge so far in the project?

“Getting the fit right is probably the most difficult aspect of the project. I am always adjusting my patterns, and probably always will be. Just when I think I have a perfect pattern, I notice something that isn’t quite right.”

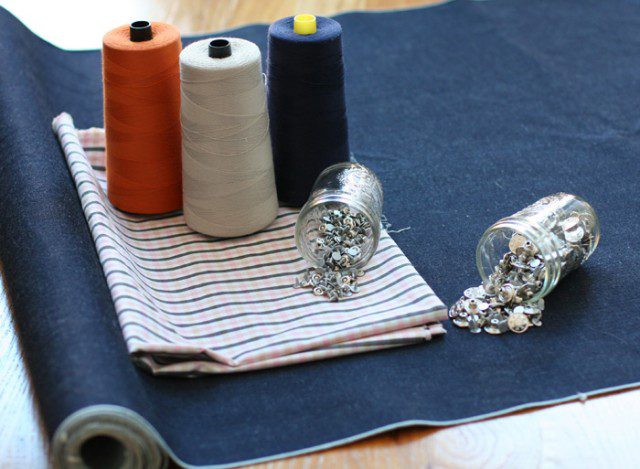

“Another challenge is sourcing quality materials and hardware in small quantities. I want to use professional grade rivets, thread, and denim when making jeans. Most general purpose craft or fabric stores don’t sell the same hardware, thread, or fabric that is used by professionals. Using the right materials makes a big difference in the overall appearance of the final jeans.”

Can you give us a little insight into the equipment you need to take the first steps in a project like this?

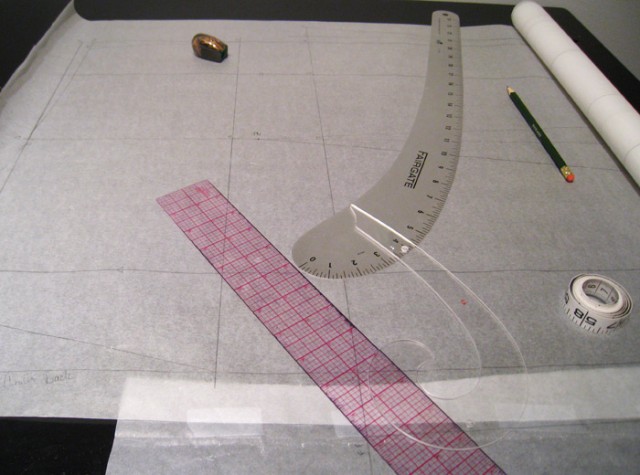

“The first thing you need is a decent sewing machine that can handle heavy thread and multiple layers of denim. You will also need a good sharp pair of scissors for cutting pattern pieces, trimming seam allowances, and clipping threads. I frequently use chalk to make marks for positioning pockets and top-stitching, as well as various rulers and curves for measuring and pattern drafting. An iron is also essential for pressing open seams and making things lay flat. I actually did a post on my blog with a more detailed list and pictures of these tools.”

So, let’s talk a little about the jeans you have made. How many jeans have you produced so far?

So, let’s talk a little about the jeans you have made. How many jeans have you produced so far?

“I’ve produced five or six pairs of jeans that I can actually wear. Throughout the process though, I made countless sample pairs of jeans out of cheap practice fabric to adjust the fit and try new techniques.”

What can you tell us about the fabric and construction of the jeans?

“I use all Cone Mills White Oak selvage denim. The denim is unwashed and in various weights ranging from 11.5 oz. for a natural coloured pair of jeans, to 13.5 oz. for a dark indigo pair. All of the construction is single needle with hand felled inseams and yokes. I don’t have any special folders, double needle waistband machines, or double needle top-stitching machines. Everything is pretty much done by hand on one sewing machine. I use an overlock machine on a couple of areas, but otherwise all the stitching is a basic lockstitch.”

How did you go about designing the fit and producing the patterns?

How did you go about designing the fit and producing the patterns?

“I used a pattern making book to create a very basic pattern using measurements taken from my body. This initial pattern didn’t have pockets, a yoke, or any style details. It was simply a representation of my body from the waist down. At this point I began to make the necessary adjustments that would turn it into a jeans pattern. I adjusted the shape of the leg, added pockets, button fly pieces, a yoke, and a waistband.”

“From here I made several pairs of sample “jeans” out of muslin. With each sample, I would make adjustments to the pattern, and then make another sample to test the fit. Once I was satisfied with the way my pattern fit, I cut the pattern out in some denim. Thin muslin will drape and stretch differently than heavy denim, so the last step was seeing how the pattern fit with actual denim.”

Was there any brand or fit you used as a template?

Was there any brand or fit you used as a template?

“I didn’t base the pattern off of any particular brand or model. I just wanted a basic straight leg, five pocket, button fly pair of jeans. My main goal was finding a balance between overly tight and too baggy.”

Are there any tips or tricks you could share with our readers if they are considering making their own pair of jeans?

“The learning process is going to be different for everybody. Practice a lot on cheap scrap fabric before you cut into nice denim. This will give you a chance to learn your pattern, hone your sewing skills, and adjust the fit. Don’t rush this part of the process. If you aren’t completely happy with your practice garments in terms of fit and construction, you won’t be happy with your final jeans either.”

“Try to be patient as you learn. Making clothing can be very time consuming so try to enjoy all aspects of the process, not just the final product.”

Which pair are you most proud of?

“If I had to pick just one, my everyday go-to pair of jeans are probably my favorite pair. I used a 12.5 oz. blue line Cone Mills selvage denim and they have broken in really nicely. The topstitching and construction in general turned out really clean. My only complaint is the yoke angle in the back. It was a little shallow on this version of my pattern, but I corrected this for future pairs of jeans.”

“I also really like the pair of jeans I made from natural coloured selvage denim. They are a nice off-white, a little lighter in weight (11.5 oz.), and good for warmer weather.”

How do you wear and treat in your dry denim jeans – any special routines?

How do you wear and treat in your dry denim jeans – any special routines?

“Not really, I just wear the jeans. I know some people like to get in the tub with their jeans on and wear them until the jeans dry. Cotton is vulnerable to stretching too much when it is wet, so I don’t do this with my jeans. I don’t keep track of washes, or put them in the freezer either. Smelly denim and ice cream should never be in contact with each other.”

“I basically wash the jeans when they need to be washed. I soak them in a tub, inside out, with warm water for a couple hours and use a little Woolite Black detergent. After a good rinse, I hang them to dry in the sun. I never put any of my handmade clothes in a dryer.”

Are there any up-coming or unknown brands/craftsmen/artisans that you think are worth looking into?

Are there any up-coming or unknown brands/craftsmen/artisans that you think are worth looking into?

“I’m not sure if they count as “unknown” brands at this point, but there are some great craftsmen and artisans right here in Nashville. Emil Erwin is a leather and canvas carrygoods company. Otis James has a line of ties and caps. And then of course is Imogene and Willie, known for their amazing jeans, but they also make shirts, jackets, and sell other accessories too.”

What are the next garments up for design in this project?

“I just finished some lightweight summer chinos. Up next, I might work on some “polo” shirts, and from there a simple unstructured jacket. Denim is probably my favorite fabric to work with, but I only need a couple good pairs of jeans, and I always want to be working on new patterns and different types of garments.”

Where do you see the project taking you in the next five years?

Where do you see the project taking you in the next five years?

“I hope to be having as much fun as I am now in five years. Eventually I want to be able to make a tailored wool suit. I’ve also considered launching a small line of products for my supply shop, not necessarily clothing, but I have some ideas I’ve been kicking around.”

When Taylor was starting out he found it difficult to source the raw materials and components in smaller numbers needed to make one offs. So he has also set up a small web store where you can purchase the materials necessary for making your own clothing. Check it out here.

You can also see the detailed account of Taylor’s journey here on his blog. There you can find plenty of tips if you feel inspired to follow his lead and make some garments of your own.

3 comments

Very impressive!

Możesz także dostosować monitorowanie dla niektórych aplikacji i natychmiast rozpocznie regularne przechwytywanie migawek ekranu telefonu.

Dzięki programowi monitorowania rodziców rodzice mogą zwracać uwagę na czynności wykonywane przez ich dzieci na telefonie komórkowym oraz łatwiej i wygodniej monitorować wiadomości WhatsApp. Aplikacja działa cicho w tle urządzenia docelowego, nagrywając wiadomości konwersacyjne, emotikony, pliki multimedialne, zdjęcia i filmy. Dotyczy każdego urządzenia z systemem Android i iOS.